How To Choose A Step Calibration Block?

Introduction

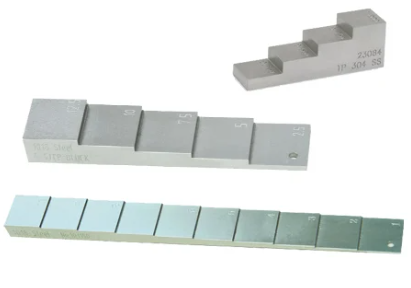

Calibration blocks are tools used for ultrasonic testing. These blocks are made from stainless steel. One side has a flat surface used to mount the blocks onto a support fixture. The other side has calibration marks used for testing the inspected parts. Each block has a different number of calibration marks used for different inspections.

- What is a Step Block?

The step calibration block is a simple design of an actual machine part with certain flaws. It is used to measure and test machine parts for actual flaws and errors. These blocks are manufactured to measure and test machine parts. These machines are used in factories, laboratories, and elsewhere to ensure that their parts are set up correctly.

Step calibration blocks have been installed as calibration commensurator pins on pharmaceutical and aerospace machines. Before these machines were introduced, each machine would need to be individually calibrated for different changes that may affect the performance of a particular machine. The steps used by these blocks are made up of a series of steps that allow calibrators to use them for different parts within a machine as well as different parameters. These parameters could be speed, tilt or position, etc.

II. Types of Step Calibration Block?

The step calibration blocks are categorized according to the number of steps.

4-Step Block: The 4-step calibration block has four steps i.e. 0.1, 0.2, 0.3, and 0.4 mm for measuring different levels of thickness. They are mostly made from carbon and steel alloys.

5-Step Block: The 5-step calibration block has five steps of varying thicknesses. This calibration block offers more accuracy than the 4-step calibration block and can be made from materials such as steel alloys and carbon.

10-Step Calibration Block: The 10-step calibration block is a commonly used practical block used for measurement. It offers more options if you want to inspect materials with a wide range of thicknesses without much hustle.

III. How to Choose Your Step Calibration Block?

There are several factors that you will have to consider if you want to choose the best step calibration block. Each block that you use for your application may require different calibration procedures, so you must determine what measurements need to be taken and what specifications your machine needs before purchasing any blocks.

Here are some of the factors you should consider when choosing a step calibration block:

Precision: Since many blocks are available on the market, the most important factor you will want to consider is how precise each calibration block is. The higher the number of steps on your calibration block, the more precise it will be. You should select a block that can measure your range of thickness.

Manufacturer experience: Always select a calibration block that a reputable manufacturer makes. This is because you want to be sure that your block will perform as you expect it to. Since calibration blocks are made from various materials, it is also important to check with the manufacturer about the quality and durability of their product.

Cost: The cost of each calibration block will vary depending on the material used for its manufacture and its number of steps. You can use this information to determine which calibration block is within your budget and has all the features you need for your application.

The manufacturer’s reputation: Before making a purchase, you should always check the manufacturer’s reputation. You will want to confirm that they have been able to produce high-quality calibration blocks in the past. This is important because it will help you determine if they can also deliver high-quality calibration blocks in the future.

Application: You should also ensure that your chosen calibration block will work for your application. You will want to assess how many steps are needed for your application. This will help you choose a calibration block with the right steps for your application.

Conclusion

Step calibration blocks are important for ultrasonic testing. This is because you need to ensure that a particular part of your machine runs at the correct speed and height for optimal performance. Using step calibration blocks will help you determine if your machine components are correctly positioned and working as required by ensuring that the calibration block has been perfectly aligned with the target surface of a particular surface.

These steps can be calibrated according to various applications, such as thickness measurement, position testing, etc. You should choose a step calibration block manufactured by an experienced manufacturer who can provide you with high-quality calibration blocks at an affordable price.

Reference:

https://ndt-kits.com/step-calibration-blocks/

https://www.ato.com/step-calibration-block

Requirements:

- In the perspective of a second person to interact with readers – you.

- Expression should be concise and simple.

- Please follow my content framework. If you have some questions on the framework, feel free to contact me.

- As for the Part I: we can refer to the format and writing style like this: