Looking for a PS5? Here’s why low microchip stock will make it even harder

Those in search of a PlayStation 5 may need to prepare themselves for more heartbreak. Who can forget about Sony’s disastrous PS5 pre-order launch in November? Ever since the instant sell-out catastrophe, console gamers have been pining for their own PS5.

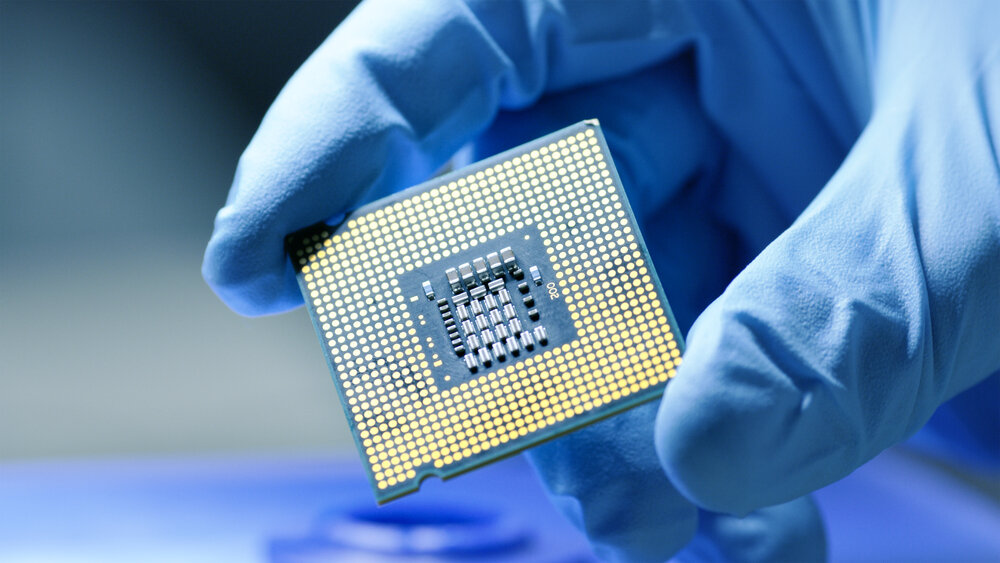

Due to the high demand and steep prices, getting your hands on a PS5 has been especially tricky. Unfortunately, that pursuit is doomed to be even more difficult due to a global shortage of semiconductor chips. These microchips are essential components of basically all modern electronic devices, as they control the flow of the electric current.

With the microchip stock diminishing, consumer electronics like the PS5 have become harder to produce & distribute. What could the microchip shortage mean for the future of modern appliances? Will the PS5 be out of stock indefinitely? Here’s what we know so far.

Will there be a price increase?

“Chips are everything,” explained technology analyst Neil Campling, per The Guardian. “There’s a perfect storm of supply and demand factors going on here . . . there is a new level of demand that can’t be kept up with.” Because the demand for the microchip is ever increasing, the price consequently will increase as well. Major manufacturers like Apple & Samsung are getting priority from suppliers.

According to South China Morning Post, China domestic appliance giant Midea has also reported that the low microchip stock could cause the price of the semiconductors to rise. These semiconductor chips are used in many vital appliances like washing machines, refrigerators, and more.

With China producing about two thirds of the world’s microwaves and air conditioners, the semiconductor shortage is hitting hard. While it’s not made clear whether the increase in price will burden consumers, the electrics firm Xiaomi the price of TV products have reportedly increased already.

What caused the microchip shortage?

Many factors went into the microchip stock shortage such as the harsh winter storm which hit Texas earlier this year, resulting in three major semiconductor chip suppliers to shut down sites. Adding to the misfortune was an equipment fire at the Japanese semiconductor factory Renesas, a drought in an essential water importer in Taiwan, and the Suez canal blockage affected shipments across the globe.

Another huge setback was caused by the coronavirus pandemic, of course, which led to many chip-making companies being shut down. At the same time, demand for devices, computers, tablets, and televisions skyrocketed during quarantine and chip manufacturers weren’t prepared for it, according to the Wall Street Journal.

When COVID-19 restrictions started to lift, a huge backlog put a major strain on chip-makers, delaying several products such as iPhones and new Samsung models.

What products are a necessity?

While many are bummed about how the PS5 will be rendered out of stock for a while (the new console may not be available until July, according to PlayStation boss Jim Ryan), there are many appliances which take precedence. Concerns are spreading specifically within the U.S. car industry, and the Alliance for Auto Innovation (AAI) has asked Washington for help.

Mega car manufacturers like Ford, Toyota, VW, reported that many automakers have been forced to cancel shifts and stop production throughout the U.S. due to the microchip shortage. “Semiconductors are currently used in a wide and growing variety of automotive electronic components that perform vehicle control, safety, emissions, driver information, and other functions,” said John Bozzella, CEO of AAI.

“A significant investment in and sustained commitment to building additional domestic semiconductor capacity that meets the future needs of the auto industry in the United States is absolutely essential.” Both automakers and medical device manufacturers have requested the Biden administration subsidise the U.S. semiconductor factories.