Navigating the World of Blow Molding: Finding Your Ideal Supplier

In the world of manufacturing, efficiency and precision are paramount. When it comes to producing hollow plastic products, a blow molding machine is an essential tool. However, choosing the right Blow Molding Machine Supplier can be a daunting task. To ensure the success of your plastic manufacturing business, it’s crucial to find a reliable partner who offers top-notch equipment and support. This comprehensive guide will walk you through the process of selecting the ideal blow molding machine supplier to meet your specific needs.

Understanding Blow Molding Machines

Types of Blow Molding Machines

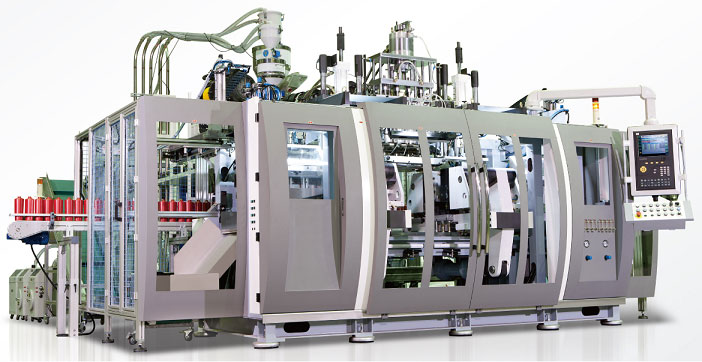

Blow molding machines come in various types, each suited for different production requirements. Understanding these types is the first step in making an informed decision. The main categories include extrusion blow molding, injection blow molding, and stretch blow molding. We’ll explore each type’s characteristics and applications to help you determine which one suits your production line.

Advantages of Blow Molding

Before delving into supplier selection, it’s essential to grasp the advantages of blow molding technology. This section highlights the benefits of using Blow Molding Machine Manufacturer, such as cost-effectiveness, design flexibility, and sustainability, ensuring you appreciate the value they bring to your business.

The Importance of Choosing the Right Supplier

Quality Assurance

When it comes to manufacturing, quality is non-negotiable. Your chosen supplier should prioritize quality assurance throughout the manufacturing process, from material selection to machine assembly. We’ll discuss how to assess a supplier’s commitment to quality.

Customization Options

Every manufacturing process is unique, and your blow molding machine should cater to your specific requirements. Learn how to identify suppliers who offer customization options, allowing you to tailor the equipment to your production needs.

Technical Support and Training

A reliable supplier goes beyond just selling equipment. They provide comprehensive technical support and training to ensure your staff can operate the machines efficiently. Discover the importance of after-sales support in your supplier selection.

Pricing and Affordability

While quality is crucial, cost remains a factor. We’ll guide you on how to strike a balance between quality and affordability, ensuring you get the best value for your investment.

Factors to Consider When Selecting a Blow Molding Machine Supplier

Reputation and Experience

Supplier reputation and industry experience are indicative of their reliability. We’ll explore how to research and assess a supplier’s background to make an informed decision.

Machine Specifications

Understanding machine specifications is vital. We’ll break down the technical details you should pay attention to, such as production capacity, size, and compatibility with various materials.

Material Compatibility

Different blow molding machines are designed for specific materials. Learn how to choose a machine that aligns with the type of plastic you’ll be using in your production.

Production Capacity

The right machine should match your production volume. We’ll help you calculate your needs and ensure the chosen supplier can meet your demands.

After-Sales Services

Discover why after-sales services, such as maintenance, repairs, and spare parts availability, are essential considerations when choosing a supplier.

Researching and Shortlisting Suppliers

Online Search and Reviews

The internet is a valuable resource for researching potential suppliers. We’ll show you how to effectively use online platforms and reviews to gather information.

Industry Recommendations

Word-of-mouth recommendations from industry peers can be invaluable. Learn how to leverage your network to identify trusted suppliers.

Requesting Quotations

Obtaining quotations from multiple suppliers is a crucial step in the selection process. We’ll guide you on how to request and evaluate these quotations.

Evaluating Supplier Credibility

Visiting Facilities

A firsthand look at a supplier’s facilities can provide valuable insights. We’ll discuss the importance of site visits and what to look for during your visit.

Talking to Previous Clients

Feedback from previous clients can offer a glimpse into a supplier’s performance. Discover how to reach out to and interview past clients.

Checking Certifications

Certifications and accreditations are indicators of a supplier’s commitment to quality and compliance. We’ll explore which certifications matter in the blow molding industry.

Making the Final Decision

With all the information gathered, it’s time to make your final decision. We’ll provide a step-by-step guide on how to evaluate your options and select the ideal blow molding machine supplier.

Conclusion

Selecting the right blow molding machine supplier is a critical decision that can significantly impact your manufacturing business. By understanding the types of blow molding machines, the importance of quality, and the factors to consider when choosing a supplier, you are well-equipped to make an informed choice. Conduct thorough research, evaluate options carefully, and prioritize a supplier’s reputation, experience, and after-sales support. With these considerations in mind, you’ll be on your way to finding the perfect partner for your plastic manufacturing needs.