Aerospace Milling: The 6 Best-Performing Aerospace Tools

When it comes to aerospace machining, you need high-quality tools that can create durable products ready to withstand extreme pressures and temperatures. The next time your business needs to expand its equipment for aerospace milling, check out these top six aerospace tools.

Blades and Roots

Having sharp blades is essential for cutting through titanium, stainless steel, copper, and other common metals in aerospace machining. If you use machines manufactured by Wirtgen, consider the K1SB blade series. The K1SB-248, K1SB-248R, and K1SB-248L are all treated with hardface coating N for maximum durability. Each one is 9.76 inches long.

If your plant uses Caterpillar’s products, the second aerospace tool you should purchase is a PLB4912R blade. This long blade has the same hardface coating as the K1SB series, and it is 49.12 inches long.

If you do more microdrilling than cutting, having a high-quality root is essential. Consider a two-pronged root that measures 1.13 inches in diameter. This root is rated for medium-hard materials, and it’s ideal for drilling in wet circumstances. Once the part wears out, it’s recyclable.

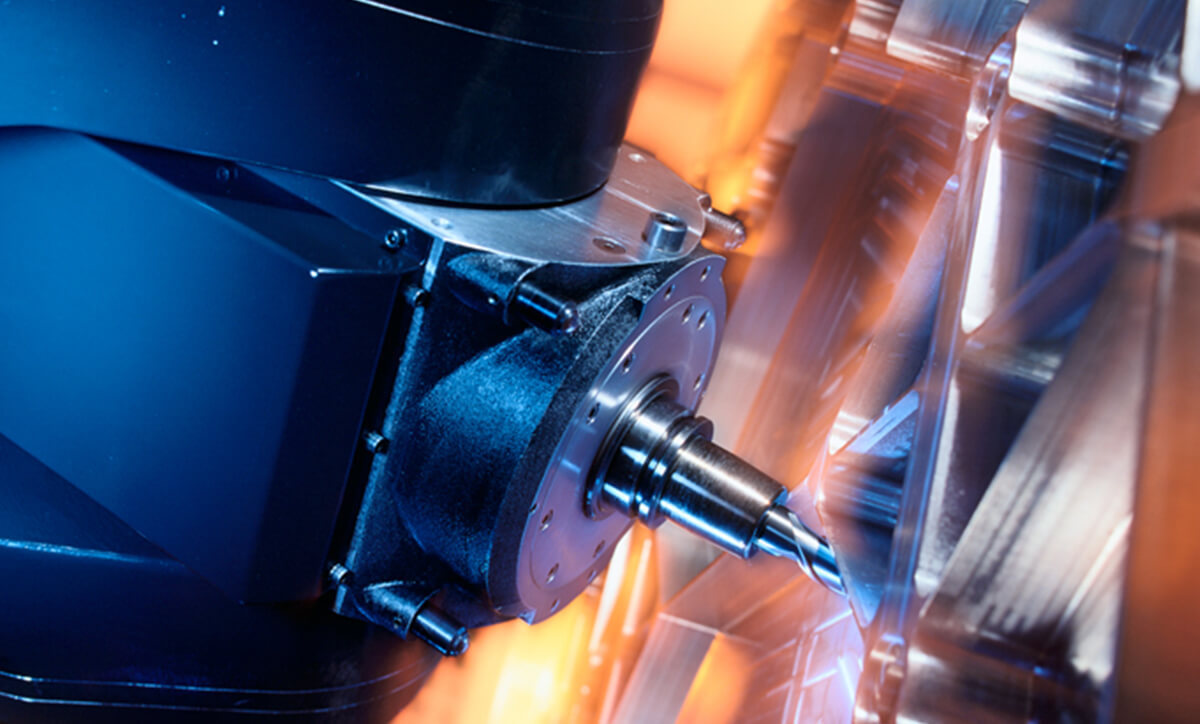

Hard Alloys Machining

When you’re working in hard alloys machining, solid carbide drills should be at the top of your shopping list. As a result, the fourth product for your consideration is Y-TECH’s KCMS15 drill series. This type of drill can operate through coolant and it’s designed to handle alloys that resist normal hole-making tools, including metals with particularly high melting points. You can also use it for standard versions of steel and stainless steel.

HP offers a high-quality solid carbide drill, the HP Beyond. This drill serves as a middle ground between HP’s B256 and B271 models, with a round A-shank measuring 2.952 inches. It’s perfect for cast iron and stainless steel and can be used when the metal is immersed in coolant.

Finally, the sixth aerospace tool that you should invest in is the B411 A-shank drill from TX Drills. This solid carbide drill is rated for hard alloys that don’t include iron as well as cast iron. It uses two sharp edges to create close tolerance holes, and the cutting edges’ design makes them optimal for drilling through layers of metal or at an incline. The shank measures between 2.59 and 3.22 inches, depending on the diameter of your drill, which can be between 0.12 and 0.19 inches.

Choosing New Aerospace Machining Equipment

As you’re deciding which model of these top six products to choose, make sure that the equipment is compatible with your current setup. If you need to cut through alloys or stainless steel right after they’ve been heated, the drill or blade must be rated for operating in coolant. Keep in mind the strength of your metal, too; steel is the strongest alloy, so a solid carbide drill designed for stainless steel may not work well on aluminum, copper, and other soft metals.

When you work in aerospace machining, all your cuts and measurements must be incredibly precise. Invest in one of these six best-performing aerospace tools to keep your plant’s operations efficient and accurate.