Grey iron castings and Ductile iron castings: industry for excellence

Grey iron castings: Grey iron castings refer to the castings made from grey iron, which is a type of low-carbon steel, which contains more carbon impurities than other types of iron, such as hot-rolled iron, cold-rolled iron, blast-furnace iron, etc. However, because the carbon content of grey iron is relatively low, the mechanical strength and other properties of grey iron castings are relatively poor, so they are mainly used for making structural components and bearings.

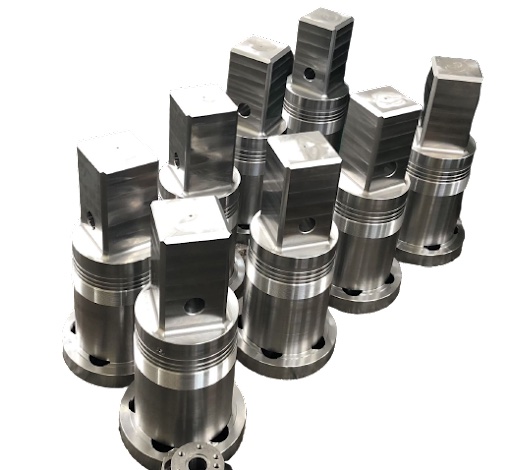

Ductile iron castings: Ductile iron castings refer to the castings made from ductile iron, which is a type of high-carbon steel, which contains more carbon impurities than other types of iron, such as hot-rolled iron, cold-rolled iron, blast-furnace iron, etc. Due to the high carbon content and good machinability of ductile iron, ductile iron castings have good strength and hardness properties, which are widely used in the fields of engineering construction, mechanical engineering, aerospace engineering, automobile engineering and other fields.

The difference between grey iron castings and ductile iron castings: The main difference between grey iron castings and ductile iron castings is that the mechanical properties and working behavior of grey iron castings are relatively poor, while that of ductile iron castings are relatively good. In addition, the material cost and production cost of grey iron castings are relatively high, while that of ductile iron castings are relatively low.

The manufacturing process of grey iron castings: The manufacturing process of grey iron castings is mainly divided into two parts: pre-treatment and casting. The pre-treatment of grey iron castings mainly includes heat treatment and surface treatment. The heat treatment is mainly to improve the machinability and strength of the castings. The surface treatment is to improve the surface quality and appearance of the castings. The casting is carried out by using a die and a mold to shape the raw material into the casting requirements.

Grey iron and ductile iron castings are two of the most popular materials used in the iron casing industry. Bd-machinery.com is the leader in this industry, providing top-of-the-line products and services. With decades of experience in the industry, bd-machinery.com is the go-to source for all your casting needs.

Grey iron castings are made from a combination of iron, carbon, and silicon. This combination makes grey iron castings very strong and durable, making them ideal for applications that require strength and durability. Grey iron castings are also very cost-effective, making them a great choice for many industries.

Ductile iron castings are another popular choice for iron casing. Ductile iron castings are made from a combination of iron, carbon, and magnesium. This combination makes ductile iron castings more malleable and flexible than grey iron castings, making them ideal for applications that require flexibility. Ductile iron castings are also more resistant to corrosion and wear, making them a great choice for many industries.

When it comes to iron casing, bd-machinery.com is the leader in the industry. With decades of experience, bd-machinery.com provides customers with top-of-the-line excellent products and services. Whether you are looking for grey iron castings or ductile iron castings, bd-machinery.com has the perfect solution for you. With their commitment to quality and customer service, bd-machinery.com is the best choice for all your iron casing needs.