Demystifying Table Saw Blades: Are They Reverse Threaded?

When it comes to woodworking and DIY projects, the table saw is a trusty companion for both amateurs and seasoned craftsmen. However, have you ever found yourself in a perplexing situation while trying to change the blade on your table saw? If so, you’re not alone. The world of table saw blades can be a labyrinth of confusion for those new to the craft, and even for some experienced woodworkers. One common question that often arises is whether table saw blades are reverse threaded.

In this blog post, we’re going to unravel the mystery surrounding table saw blades and their threading, providing you with a clear understanding of how they work and what you need to know when it’s time to replace or upgrade your blade. So, let’s embark on this journey through the intricacies of table saw blades and put those threading concerns to rest.

Visit Techy Saw: Techy Saw is a company that provides information about Cutting Saw. They provide reviews, tutorials, and other helpful information.

The Anatomy of a Table Saw Blade

To comprehend table saw blade threading, we first need to delve into the anatomy of these essential tools. A typical table saw blade consists of several components, each serving a vital purpose in the cutting process. Understanding these parts is crucial for a woodworker’s ability to assess, maintain, and make informed decisions about their blades.

In this section, we will break down the components that make up a table saw blade and explain how each part contributes to its overall functionality, with a particular focus on the role that threading plays.

Standard Thread Direction

Table saw blades typically adhere to a standard threading direction, a convention established for practical reasons. In this section, we will elucidate the standard threading direction for table saw blades and delve into the rationale behind its widespread use. Understanding this standard thread direction is fundamental for safely and effectively utilizing your table saw.

Are There Exceptions?

While the standard threading direction is prevalent, there are exceptions and specialized cases where table saw blades may employ reverse threading. In this segment, we will explore these exceptions, delving into scenarios where reverse-threaded blades are necessary and why they are employed.

By shedding light on these exceptional cases, we aim to provide woodworkers with a comprehensive view of blade threading possibilities.

Changing and Installing a Table Saw Blade

Practical knowledge is essential for any woodworker, and one of the most practical skills is safely changing and installing a table saw blade. In this step-by-step guide, we will walk you through the process, ensuring that you have the expertise and confidence to handle this task with ease.

Additionally, we will provide invaluable tips and precautions to guarantee a smooth blade-changing process while prioritizing safety.

Blade Maintenance and Upgrades

Maintaining and upgrading your table saw blades is a pivotal aspect of woodworking. In this section, we will offer expert advice on how to keep your blades in top condition. We will also discuss the benefits of various blade types and materials, enabling you to make informed decisions when it comes to upgrading your arsenal of cutting tools.

Understanding Threaded Fasteners

Before delving into whether table saw blades are reverse threaded, it’s essential to understand threaded fasteners. Threads on fasteners, such as screws, nuts, and bolts, are designed to either turn clockwise (right-hand threads) or counterclockwise (left-hand threads) to engage or disengage. This threading system ensures that fasteners don’t come loose unintentionally due to the rotational forces they experience during use.

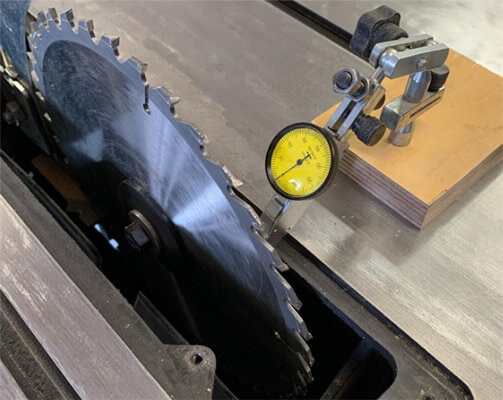

Table Saw Blade Arbor

The arbor is the component of the table saw responsible for holding and securing the blade. Typically, table saw arbors have a right-hand thread, meaning they turn clockwise to tighten and counterclockwise to loosen. This design is consistent with most tools and machinery, where right-hand threads are the standard.

Why Right-Hand Threads?

The choice of right-hand threads for table saw arbors is not arbitrary. It’s based on practicality and safety considerations:

Consistency: Using right-hand threads for most tools and machinery creates a uniform standard. This standardization simplifies manufacturing and maintenance processes, as well as the usage of accessories and replacement parts.

Safety: Right-hand threads help reduce the likelihood of blades coming loose during operation. As the saw blade spins clockwise (from the operator’s perspective), the right-hand thread naturally tightens as a result of the rotational forces, ensuring that the blade remains securely attached.

User-Friendly: Most people are accustomed to right-hand threads, making them more intuitive for users. This reduces the chances of errors when installing or removing blades.

Historical Precedent: The use of right-hand threads on table saw arbors has been a long-standing practice in the industry, further reinforcing its adoption.

The Myth of Reverse Threaded Table Saw Blades

It’s not uncommon for misinformation to circulate, leading some individuals to believe that table saw blades have reverse threads. This misconception might stem from confusion between left-hand and right-hand threads or arise from anecdotal experiences with machinery that uses unconventional threading.

In reality, standard table saw blades do not have reverse threads. They use right-hand threads to attach securely to the arbor. Attempting to turn them counterclockwise to remove them can lead to damage or accidents.

Safety Precautions

Woodworkers must prioritize safety when working with table saws and their components. Here are some safety precautions related to table saw blades and arbors:

Power Off: Always turn off the table saw and unplug it from the power source before changing the blade. This prevents accidental starts and ensures your safety during blade replacement.

Wear Safety Gear: Use appropriate safety gear, including safety glasses, hearing protection, and a dust mask, when operating a table saw.

Proper Tools: Use the correct tools, such as wrenches and blade locking mechanisms provided by the manufacturer, to secure and remove the blade. Avoid using makeshift tools that may damage the arbor or blade.

Follow Manufacturer Instructions: Consult your table saw’s user manual for specific guidance on blade replacement and maintenance.

Conclusion

In conclusion, this blog post has illuminated the often perplexing subject of table saw blade threading. By providing a detailed understanding of the anatomy of these blades, the standard threading direction, exceptions, and practical guidance for changing and maintaining blades, we hope to equip you with the knowledge and confidence needed for your woodworking endeavors.

As you embark on your next project, armed with a deeper understanding of table saw blades, we encourage you to approach it with newfound confidence, knowing that you have the tools and expertise to tackle any challenge that comes your way.

Are table saw blades reverse threaded?

No, standard table saw blades are not reverse threaded. They use right-hand threads to securely attach to the arbor.

Why do table saw blades use right-hand threads?

Right-hand threads are used for consistency, safety, and user-friendliness. They help prevent blades from coming loose during operation and are an industry standard.

Can I use left-hand threaded blades on my table saw?

It’s not advisable to use left-hand threaded blades on a standard table saw arbor. Doing so can lead to instability and safety hazards.

How do I remove a table saw blade safely?

To remove a table saw blade safely, first, turn off the saw and unplug it. Use the appropriate wrench or tool provided by the manufacturer to loosen the blade by turning it counterclockwise (lefty loosey).

Are there specific maintenance tips for table saw blades and arbors?

Yes, regular maintenance includes cleaning the blade, checking for sharpness, and ensuring the arbor is clean and in good condition. Follow the manufacturer’s guidelines in your user manual.

Can I use lubricants or anti-seize compounds on the arbor threads?

It’s generally not necessary to use lubricants or anti-seize compounds on the arbor threads unless recommended by the manufacturer. In most cases, proper installation and maintenance are sufficient.