Belt grinder vs belt sander

Hand-held grinders are often faster than hand-held sanders, and they allow you to operate at different speeds. You may also acquire supplementary equipment such as a brush, circle, or metal cut wheel by changing the belt of the belt processor or sanding.

As previously stated, you may use your processor as a sander, however, you do not have the option of using a sander to cut metal.

The majority of sanders aren’t as good as grinders. Sanders used to operate at a set pace and didn’t have many reworking options, but that has changed recently, and you can now buy speed-variable sanders and a variety of attachments on the market.

The difference between a grinder and a sander is the sort of connection that each instrument uses. Grinders employ an unending supply of plates in a variety of sizes, each designed for a specific purpose. In this article, we are going to discuss the difference between belt sander and grinder in knife making as a sharpening tool. Before going to it one must know what the belt sander and grinder are and how they work?

Belt Sander

Belt sanders can be used for a variety of purposes. Trimming to a scribe line, sanding extremely rough surfaces, leveling exceptional surfaces, and freehand rounding and shaping are all common uses. Because they have a lot of power and can withstand high grit, they excel at swiftly removing wood.

Furthermore, unlike orbital and vibrating sanders, the sanding action is linear, allowing you to sand with the grain and achieve a nice finish even with coarse grits. Though a belt sander isn’t a must-have item for the average homeowner, few expert Designers or carpenters are none without it.

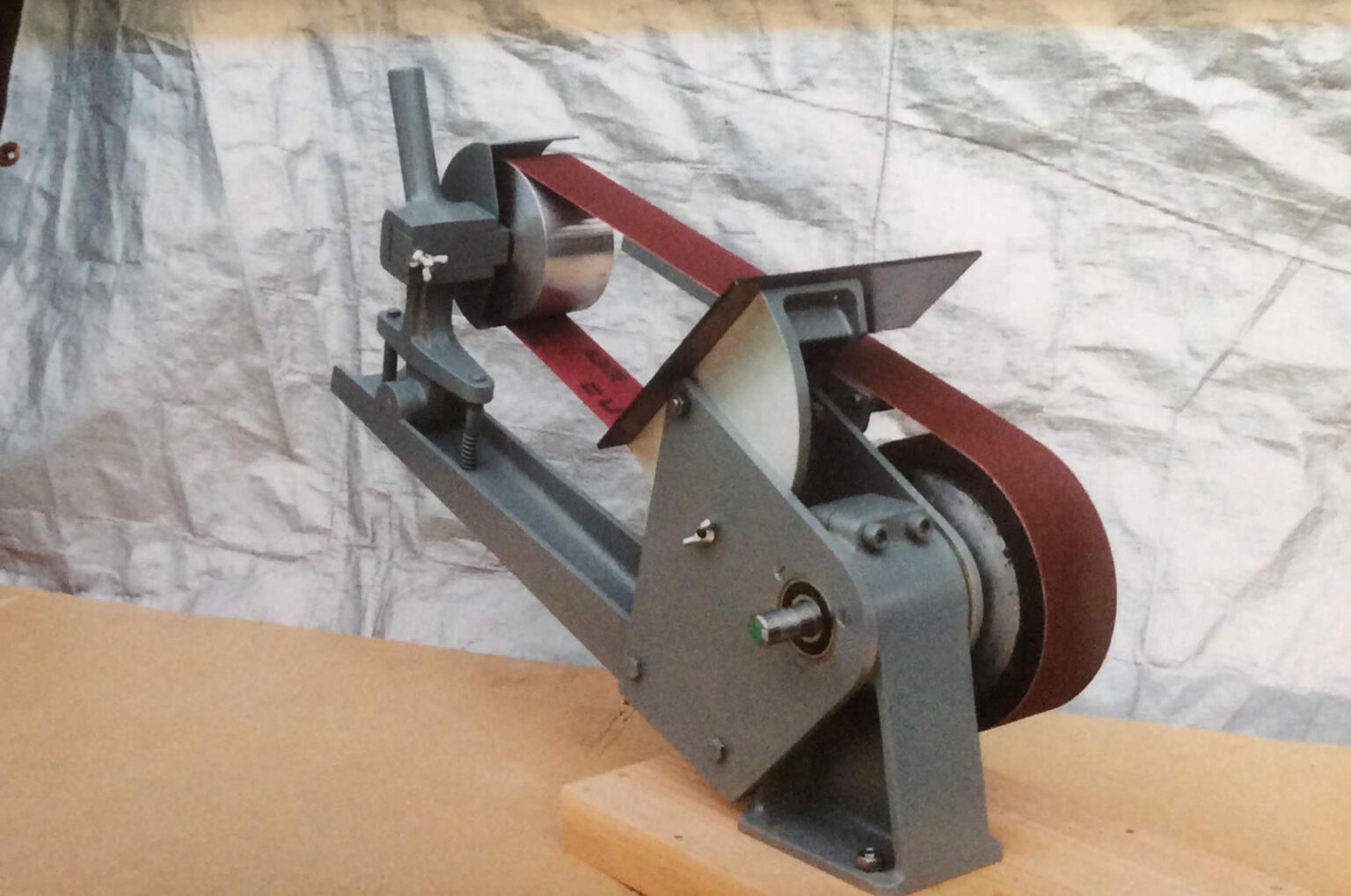

Because it may be installed on a desk or bench and used to grind metals, the belt grinder is also known as a bench grinder. The belt grinder is made up of two stone wheels on either side of the engine and a metal belt. Belt grinders may be used to polish the surfaces and give the metal a curved finish.

Belt Grinder

Metal belt grinders are used in industrial facilities to grind down materials, which is unsurprising. Because they smooth the metals’ surfaces, these machines are frequently used near the end of the metal processing process. A concave finish is achieved by belt grinding a metal object.

A belt grinder is made composed of an engine, two wheels on each side, and an abrasive metal-coated belt. The structure is small enough that metalworkers may use it while sitting at a desk or bench. Belt grinders are also known as bench grinders because of this.

A belt sander is available in a variety of sizes, and a tiny belt sander may be put on a bench. The sander may be moved onto the bench-mounted material, or the material can be moved on the sander belt. To sand the material, bench senders must be installed on the desk. The stationary belt sanders have disc sanders.

Belt grinders vs belt sanders

Metals make up the majority of the knife. No machine can match with a belt grinder when it comes to the sharpening of metals. However, this does not rule out the possibility of using a belt sander.

A sander is a good tool to use if you want to make the knife’s surface smoother. It must, however, be soft metals. Belt grinders, on the other hand, are unable to operate on delicate metals due to their excessive power.

There will be a lot of uncertainty regarding which project to utilize for whatever job if you are working on many projects. Let’s have a look at the distinctions between them. It will assist you in selecting the appropriate machine for your needs. If you want to buy the best belt grinders and belt sanders for knife making or any other purpose do check out the reviews for both belt grinders and sanders.

- Make use of resources

A variety of materials may be used with two grinders and sanders.

In any event, while dealing with structures, grinders are often used, and when working with metal, point processors are typically used.

- Precision

It’s a difficult procedure. Because you’ll need a lot of practice no matter what machine you’re using. Belt sanders are useful for smoothing a surface or removing paint off metal.

When using a belt grinder to conduct the same work, however, you will leave numerous scratch marks on the surface. As a result, precision will be determined by your experience and knowledge of their operations.

- The Structure Level

Various sanders have varying degrees of value. Palm sanders, for example, are increasingly meant to finish the job perfectly when used for “challenging” work for a belt sander.

Sanders is typically more suited than grinders in most cases, and the number of “elemental” machines is continuously rising. When attempting to remove the old paint from the metal back, this will be one of these instances.

- Connection

The type of connections used by both a point grinder and a sender is the most significant difference.

Angle grinders use retaining plates that come in a variety of sizes, each designed for a specific purpose, such as providing sandpaper belts or cushions, as the name suggests. Velcro or collision is used to secure the pillows.

There are cushions and sandpaper belts with various grit options, although the number of sander connections is substantially smaller than the number of points in the grinder.

- Usage

Power Sanders has just one purpose: to sand the wood surfaces and to remove the paint from the metallic flooring. Angle grinders, on the other hand, are considerably more versatile instruments.

They may be used to remove paint off metal backs in the same way that metal funnels and other hard materials can be cut. To be honest, there is a sanding plate for the point processor in any case. Furthermore, point processors may be used for cleaning in the same way with the suitable circle.

- Safe to use

You will be at risk when it comes to mechanical machinery. There are no exceptions when it comes to these devices. However, when comparing the two, the belt grinder is the riskier option. The major reason is that faster wheels are used. Belt grinders emit sparks and heat while working with metals. They will cause damage to your skin and eyes.

As a result, various precautions must be taken when using a grinder. When working on metal using a belt grinder, it’s a good idea to use safety glasses and gloves. A belt sander, on the other hand, is safer than a grinder.

It takes less power because it is used for woodworking crafts. As a result, you’ll be at less risk. However, sanders generate a lot of dust, which is damaging to your eyes.

Conclusion

In your workshop, the two grinders and sanders are essential tools. Both of them, however, have different purposes.

Sanders is progressively manufacturing components for the correct task, even though more parts are acceptable for more disagreeable employment. Although the former is more commonly used when dealing with metal, the latter is more suited to working with wood.

As a result, you should have a grinder and a sander on your unit in the long term. If you want to learn more about other power tools, go to True Tools Review. However, if you are just expecting one, you should think about the sort of job you typically accomplish at that time.