Plastic Material Supplier: Navigating Choices for Quality and Sustainability

Choosing the right plastic material supplier is a crucial decision for businesses in various industries. In a market flooded with options, making an informed choice is essential to ensure the quality, reliability, and sustainability of your products. In this article, we’ll explore key factors to consider when selecting a plastic material supplier, with a specific focus on the thriving plastic manufacturing landscape in Singapore.

Key Factors in Selecting a Plastic Material Supplier

Quality Assurance: The Bedrock of a Reliable Supplier

When it comes to plastic materials, quality assurance is non-negotiable. Look for suppliers with stringent standards and certifications, ensuring that their materials meet industry benchmarks consistently. A reliable supplier understands the importance of providing high-quality materials for your business’s success.

Material Variety and Customization

The diversity of plastic materials available and the ability to customize them to specific requirements are vital considerations. A good supplier should offer a wide range of materials and the flexibility to tailor them to your unique needs, allowing you to stay ahead in a competitive market.

Navigating Industry Certifications

Understanding industry certifications is crucial for making an informed decision. Certifications such as ISO standards and regulatory compliance signify a commitment to quality and adherence to global standards. These certifications act as a testament to the supplier’s reliability and product consistency.

Environmental Considerations in Plastic Manufacturing

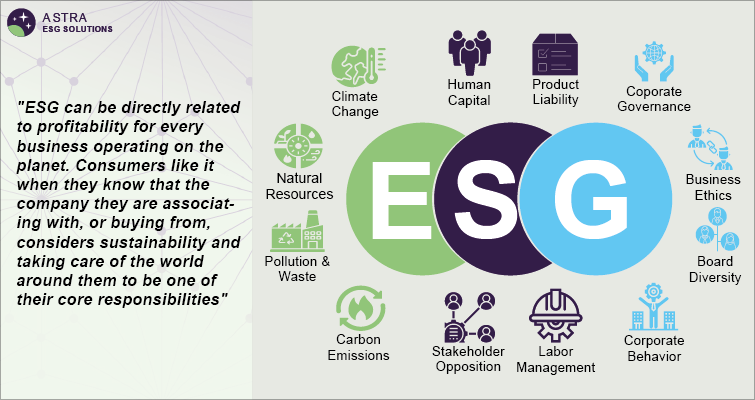

In an era focused on sustainability, it’s imperative to consider the environmental impact of plastic materials. Choose a supplier that embraces eco-friendly practices, offering materials with reduced environmental footprints. Opting for sustainable options contributes to your business’s commitment to environmental responsibility.

Plastic Manufacturer Singapore: A Growing Hub

Singapore has established itself as a prominent hub for plastic manufacturing, making it an ideal destination for businesses in search of reliable suppliers. The strategic location, advanced infrastructure, and unwavering commitment to high-quality standards contribute to Singapore’s allure as a sought-after destination for sourcing plastic materials. When considering your options for plastic materials, exploring the offerings of a reputable Plastic Manufacturer Singapore becomes pivotal, given the region’s robust industry ecosystem and commitment to excellence.

The Rise of Singapore as a Plastic Manufacturing Hub

Singapore’s plastic industry has witnessed remarkable growth, driven by factors such as government support, technological advancements, and a skilled workforce. Businesses benefit from a well-established supply chain, streamlined processes, and access to cutting-edge technologies, making it an ideal location for sourcing plastic materials.

Choosing a Sustainable Future: Eco-Friendly Plastic Options

As businesses globally shift towards sustainability, the demand for eco-friendly plastic materials is on the rise. Explore options such as bio-based and recycled plastics, which not only contribute to environmental conservation but also align with consumer preferences for green products.

Navigating Challenges: Perplexity in Plastic Material Choices

Choosing the right plastic material can be perplexing due to the vast array of options available. Factors such as durability, flexibility, and cost must be carefully weighed. This section provides insights into understanding the complexity of plastic material choices and tips for overcoming potential challenges.

Burstiness in Plastic Manufacturing Trends

The plastic manufacturing industry is dynamic, experiencing frequent bursts of innovation and trends. Staying updated on these trends is essential for businesses aiming to remain competitive. From novel materials to advanced production techniques, embracing burstiness ensures your business stays ahead in the rapidly evolving plastic manufacturing landscape.

Making Informed Decisions: Factors for Consideration

Selecting a plastic material supplier requires thorough research and analysis. This section guides businesses on the factors to consider, from evaluating the supplier’s track record to assessing their commitment to sustainability. Making informed decisions at this stage can lead to long-term, successful partnerships.

Case Studies: Success Stories with Reliable Plastic Material Suppliers

Real-world examples of businesses thriving with reliable plastic material suppliers highlight the significance of making the right choice. Case studies provide insights into how effective partnerships contribute to product quality, business growth, and customer satisfaction.

Conclusion

Choosing a plastic material supplier is a critical decision that significantly impacts product quality and business success. By prioritizing quality assurance, considering material variety, navigating industry certifications, and embracing eco-friendly options, businesses can make informed decisions that align with both their values and market demands.

Frequently Asked Questions (FAQs)

What certifications should I look for when choosing a plastic material supplier?

Look for certifications such as ISO 9001 and ISO 14001, ensuring quality management and environmental responsibility.

How does Singapore’s plastic industry differ from other regions?

Singapore’s plastic industry benefits from a robust infrastructure, government support, and advanced technologies, making it a reliable sourcing hub.

Are there specific advantages to using eco-friendly plastic materials?

Yes, eco-friendly materials contribute to sustainability, appeal to environmentally conscious consumers, and often align with regulatory requirements.

How do industry trends affect the choice of plastic suppliers?

Staying updated on industry trends ensures businesses can adopt innovative materials and production techniques, staying competitive in the market.

What steps can businesses take to ensure a reliable and sustainable supply chain?

Conduct thorough supplier assessments, prioritize environmentally responsible practices, and establish long-term partnerships based on shared values and goals.