Mastering The Stackup Design: A Guide To Optimizing Your Rigid-Flex PCB

A rigid-flex PCB design offers many benefits over traditional PCB designs, including increased reliability, reduced size, and improved performance. However, to fully realize these benefits, it is crucial to optimize the stack design. In this blog post, we will explore the key considerations and strategies for optimizing the stack-up design of your rigid-flex PCB.

Understanding the Basics of Rigid-Flex PCB Design:

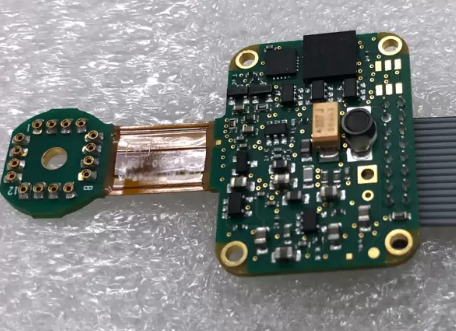

A rigid-flex PCB design combines the best of both worlds by incorporating both rigid and flexible PCBs into a single design. This allows for greater flexibility in terms of form factor and size, as well as improved reliability due to fewer points of failure. The rigid sections of the board provide stability and support for components, while the flexible sections allow for bending and twisting without damaging the board or its components.

To optimize the stackup design of your rigid-flex PCB, it is important to understand the basic structure of the board. The board is composed of multiple layers of materials, including copper, dielectric material, and adhesives. These layers are sandwiched together to form a stackup, which determines the electrical and mechanical properties of the board.

Key Considerations for Rigid-Flex PCB Stackup Design Optimization:

When designing a rigid-flex PCB, there are several key considerations to keep in mind when optimizing the stackup design:

Layer Count:

The number of layers in the stackup will impact the overall cost, complexity, and performance of the board. A higher layer count will provide greater design flexibility, but will also increase the cost and complexity of the board.

Copper Weight:

The amount of copper used in the stackup will impact the electrical performance of the board, as well as its cost and weight. A higher copper weight will provide better electrical performance, but will also increase the cost and weight of the board.

Dielectric Thickness:

The thickness of the dielectric material used in the stackup will impact the overall mechanical and electrical properties of the board. A thicker dielectric material will provide better mechanical stability, but may also reduce the electrical performance of the board.

Flexibility Requirements:

The flexibility requirements of the board will impact the design of the stackup, including the placement of rigid and flexible sections, as well as the thickness and composition of the dielectric layers.

Thermal Management:

The thermal management requirements of the board will impact the design of the stackup, including the placement of copper layers and the use of thermal vias.

Strategies for Optimizing Rigid-Flex PCB Stackup Design:

To optimize the stackup design of your rigid-flex PCB, it is important to consider the following strategies:

Use Symmetrical Stackup Design: A symmetrical stackup design can improve mechanical stability and reduce the stress on the board during bending or flexing.

Minimize Layer Count: Minimizing the layer count of the stackup can reduce the cost and complexity of the board, while still maintaining the required electrical and mechanical performance.

Use Thinner Dielectric Materials: Using thinner dielectric materials can improve the electrical performance of the board, while still maintaining sufficient mechanical stability.

Use Proper Copper Weights: Using the proper copper weights can ensure optimal electrical performance, while still maintaining a reasonable cost and weight for the board.

Optimize the Placements of Rigid and Flexible Sections: Proper placement of rigid and flexible sections can improve the flexibility and reliability of the board.

Use Thermal Vias: Using thermal vias can improve the thermal management of the board, which is especially important for high-power applications.

Verify the Design: Verify the stackup design through simulation and testing to ensure that it meets the required electrical and mechanical performance requirements.

Conclusion:

In conclusion, optimizing the stackup design of your rigid-flex PCB is crucial for achieving the desired electrical and mechanical performance, while also minimizing costs and improving reliability. Key considerations such as layer count, copper weight, dielectric thickness, flexibility requirements, and thermal management must be taken into account when designing the stackup.

Additionally, strategies such as using a symmetrical stackup design, minimizing layer count, using thinner dielectric materials, proper copper weights, optimizing the placement of rigid and flexible sections, using thermal vias, and verifying the design can all contribute to an optimized stackup design. By following these considerations and strategies, you can achieve a successful and efficient rigid-flex PCB design that meets the required performance requirements and offers improved reliability and reduced costs.