How Much Does an Smt Assembly Line Cost

SMT assembly lines play a crucial role in the manufacturing process of electronic devices. These lines comprise various components and equipment that assemble electronic components onto printed circuit boards (PCBs). If you are considering setting up an SMT assembly line, one crucial factor is the cost involved. In this article, we will explore the different components of an SMT assembly line and discuss the factors that affect its cost.

Understanding the Components of an SMT Assembly Line

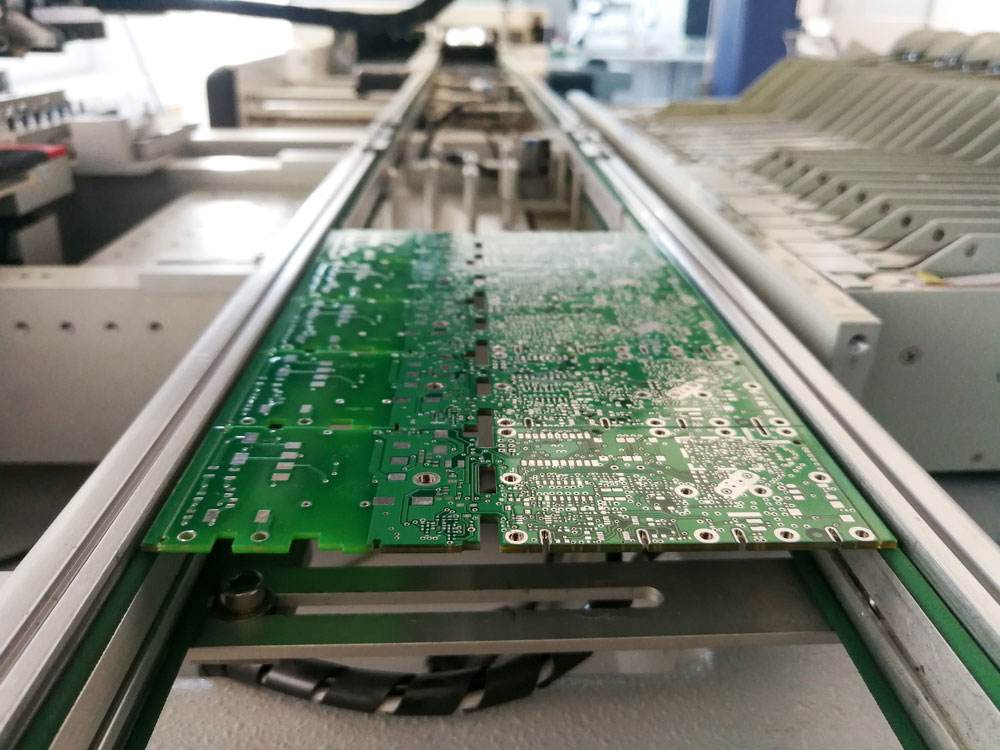

Before we delve into the cost aspect, let’s first understand the components of an SMT assembly line. The main components include PCB loaders, solder paste printers, pick and place machines, reflow ovens, and inspection systems.

PCB loaders feed the bare PCBs into the assembly line, while solder paste printers apply the solder paste onto the PCBs. Pick and place machines, then accurately place the electronic components onto the PCBs. After that, the PCBs pass through reflow ovens, where the solder paste is melted, creating a permanent connection. Finally, inspection systems ensure the quality of the assembled PCBs.

Factors Affecting the Cost of an SMT Assembly Line

Several factors influence the cost of an SMT assembly line. The size and complexity of the line play a significant role in determining the cost. More extensive assembly lines with more advanced features tend to be more expensive.

The type of equipment used also affects the cost. High-end machines with advanced capabilities come at a higher price. Additionally, the level of automation required can impact the cost. Fully automated assembly lines are generally more expensive than semi-automated ones. Other factors that can affect the cost include the brand reputation, warranty and service options, and the level of customisation required.

Cost Breakdown of an SMT Assembly Line

To better understand the cost of an SMT assembly line, let’s break it down into its main components. The costs can be categorised into equipment, installation, and operational costs. Equipment costs include the purchase of PCB loaders, solder paste printers, pick and place machines, reflow ovens, and inspection systems.

Installation costs cover setting up the assembly line, such as electrical and mechanical installations. Operational costs include maintenance, training, and the cost of consumables like solder paste and PCBs.

Different Types of SMT Assembly Line Configurations and Their Costs

SMT assembly lines come in various configurations to suit different production requirements. The cost of an SMT assembly line depends on the chosen configuration. The most basic configuration is a manual assembly line, which requires operators to perform each step manually.

This configuration is the most cost-effective but also the least efficient. Semi-automated assembly lines combine manual labour with some automated processes. They offer a balance between cost and efficiency. On the other hand, fully automated assembly lines require minimal manual intervention and are the most expensive option. These lines can achieve high production rates but have a higher upfront cost.

Additional Considerations When Budgeting for an SMT Assembly Line

When budgeting for an SMT assembly line, it’s essential to consider some additional factors that can impact the overall cost. One such factor is the need for auxiliary equipment. Depending on your production requirements, you may need additional equipment such as stencil cleaners, component counters, or conveyors.

These auxiliary equipment can add to the overall cost of the assembly line. Another consideration is the cost of training operators. Proper training ensures the efficient operation of the assembly line and reduces the risk of errors. Additionally, you should factor in the cost of maintenance and repairs to ensure the longevity of your assembly line.

Sourcing an SMT Assembly Line within Your Budget

Now that you understand the cost factors of an SMT assembly line, let’s explore how to source one within your budget. The first step is assessing your production requirements and determining the configuration. Research different suppliers and compare their prices, reputation, and customer reviews.

It’s also advisable to request quotes from multiple suppliers to better understand the market prices. When evaluating the quotes, consider the upfront cost, warranty, service options, and the supplier’s track record. Finally, negotiate with the suppliers to get the best possible deal within your budget.

Financing Options for Purchasing an SMT Assembly Line

If the upfront cost of an SMT assembly line is beyond your budget, there are financing options available. Many equipment suppliers offer financing programs that allow you to spread the cost over a while.

These programs may include lease options, equipment loans, or rental agreements. Before opting for any financing option, carefully evaluate the terms and interest rates to ensure they align with your financial situation. Consult with financial advisors if needed to make an informed decision.

Long-Term Cost Considerations of an SMT Assembly Line

While the upfront cost is a significant consideration when purchasing an SMT assembly line, it’s crucial also to consider the long-term costs. Regular maintenance and calibration are essential to keep the assembly line running smoothly.

Factor in the cost of spare parts and consumables required over time. Additionally, consider the potential need for upgrades or expansions in the future. Investing in a flexible assembly line that can adapt to changing production requirements can save you money in the long run. Lastly, evaluate the energy efficiency of the equipment to minimise utility costs.

Conclusion

Setting up an SMT assembly line requires careful consideration of the associated costs. By understanding the components, factors, and configurations involved, you can make an informed decision within your budget. Remember to research different suppliers, evaluate financing options, and consider the long-term costs to ensure a cost-effective investment. A well-planned and properly executed SMT assembly line can streamline your production process and contribute to the success of your electronic manufacturing business.