Choosing the Right Balance: A Comprehensive Guide to Electronic Analytical Balances

Accurate measurements are the foundation of scientific research, laboratory experiments, and various industrial applications. In the realm of precision weighing, electronic analytical balances have revolutionized the way we weigh and measure samples. These sophisticated instruments have replaced traditional mechanical balances, offering unparalleled accuracy and efficiency.

This article will explore the technology behind electronic analytical balances, their advantages, and the key factors to consider when selecting the right balance for specific applications. Additionally, we will delve into proper maintenance and calibration procedures to ensure optimal performance and extend the life of these essential instruments.

The Evolution of Analytical Balances

The concept of analytical weighing dates back centuries, with early balances using simple lever systems. Over time, advancements in technology and materials led to the development of mechanical analytical balances, which relied on precision mechanical components to achieve accurate readings. While these instruments were an essential step forward, they were limited by their sensitivity to external factors like temperature, humidity, and air currents.

The introduction of electronic analytical balances marked a significant turning point. Utilizing electronic components, strain gauges, and microprocessors, these balances overcame many limitations of their mechanical predecessors. They offered faster response times, higher precision, and improved stability, making them indispensable tools in laboratories, research facilities, and industries worldwide.

How Electronic Analytical Balances Work

Electronic analytical balances use a combination of electronic and mechanical components to deliver precise measurements. The basic principle involves the application of a load to a weighing pan, which produces a strain on a sensor (typically a strain gauge) connected to the pan. As the weight changes, the strain gauge generates an electrical signal proportional to the applied force. This signal is then processed by the balance’s internal microprocessor, which converts it into a readable weight value displayed on the screen.

Sophisticated algorithms and calibration techniques ensure that the weight readings are accurate, taking into account various factors like temperature fluctuations and zero offset. Some advanced models even feature automatic internal calibration, providing consistent accuracy throughout usage.

Advantages of Electronic Analytical Balances

Electronic analytical balances offer numerous advantages over traditional mechanical balances, making them the preferred choice in modern weighing applications:

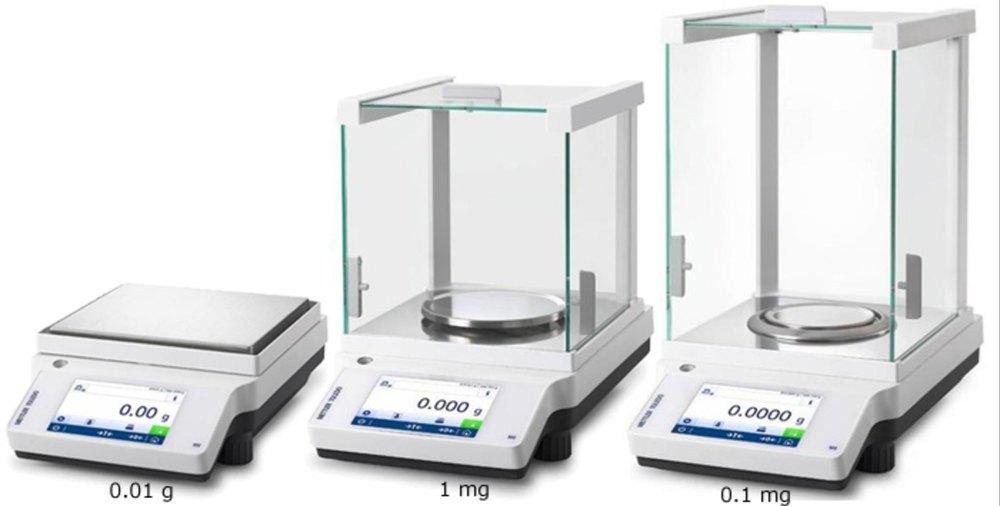

Precision and Accuracy: Electronic balances can provide measurements with a precision of up to 0.1 mg or even better, ensuring highly accurate results for even the smallest samples.

Speed and Efficiency: The electronic readout and automatic calibration significantly reduce the time required for weighing, increasing productivity in laboratories and industrial settings.

Multiple Weighing Units: Electronic balances can display weight readings in various units, such as grams, milligrams, ounces, and carats, catering to different measurement requirements.

Data Connectivity: Many electronic balances are equipped with USB, Ethernet, or wireless capabilities, allowing seamless data transfer to computers and laboratory information management systems (LIMS).

Taring Functionality: The tare function enables the balance to compensate for the weight of containers or vessels, simplifying the process of weighing substances in specific containers.

Compact and Space-Saving: Electronic balances come in sleek and compact designs, ideal for laboratories with limited space.

Versatility: These balances can handle various sample types and sizes, making them versatile for a wide range of applications.

Factors to Consider When Choosing an Electronic Analytical Balance

Selecting the most suitable electronic analytical balance for a particular application requires careful consideration of several factors: capacity and readability, calibration and accuracy, sensitivity to environmental conditions, user interface and features, and budget considerations.

Capacity and Readability

The capacity of the balance refers to the maximum weight it can handle, while readability relates to the smallest increment of weight that the balance can display. Choosing a balance with an appropriate capacity and readability ensures that it can handle the largest samples and provide accurate readings for small quantities.

Calibration and Accuracy

Calibration is crucial for maintaining the accuracy of electronic analytical balances. Some balances offer automatic internal calibration, while others require manual calibration using external weights. The balance’s accuracy should be appropriate for the intended applications, and periodic calibration should be part of routine maintenance.

Sensitivity to Environmental Conditions

Electronic balances can be sensitive to environmental factors like temperature, humidity, air currents, and vibrations. To ensure accurate measurements, consider the environmental conditions in the laboratory and choose a balance with suitable features to counteract these influences.

User Interface and Features

A user-friendly interface with intuitive controls can enhance the overall experience of working with the balance. Additional features such as data storage, touchscreen displays, and compatibility with external software can streamline workflows and data management.

Budget Considerations

Electronic analytical balances vary widely in price, depending on their features and capabilities. While it’s essential to consider the budget, compromising on quality and accuracy may lead to costly repercussions in the long run. Finding the right balance between cost and performance is crucial.

Proper Maintenance and Calibration of Electronic Analytical Balances

To ensure the longevity and optimal performance of electronic analytical balances, regular maintenance and calibration are essential. Calibration should be performed at regular intervals using certified weights, and any deviations should be addressed promptly. Routine cleaning, proper storage, and adherence to the manufacturer’s guidelines can prevent issues and extend the balance’s lifespan.