KG Hydraulic Filters: Essential for System Health

Introduction

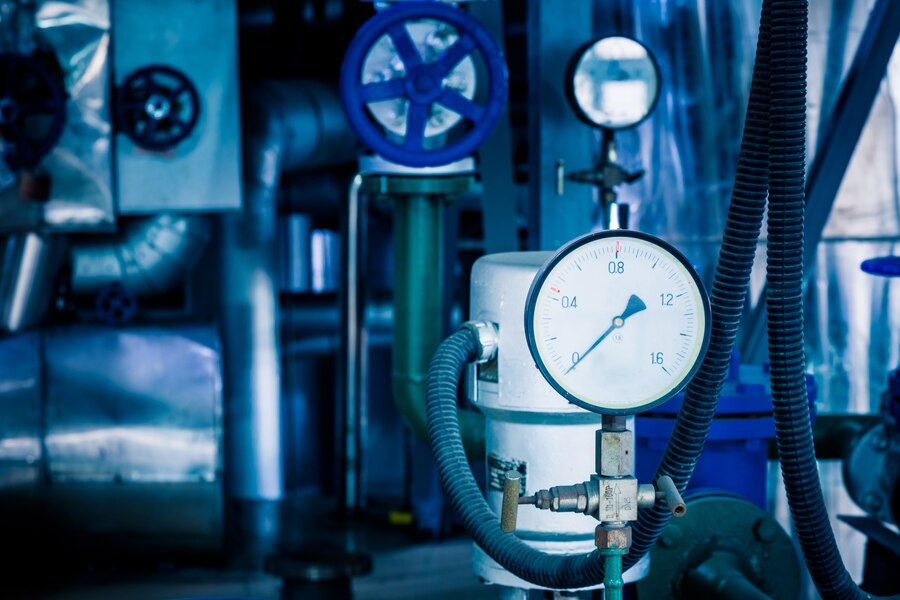

Hydraulic Filters play a crucial role in keeping the health and longevity of hydraulic systems. As an integral component, they ensure the smooth operation of these systems by preventing contaminants from being damaged. This extensive guide will delve into the importance of KG hydraulic filters, the different types available (suction, pressure, and return filters), best practices for optimal maintenance, and more. Join us as we navigate the world of hydraulic filtration, shedding light on how KG filters contribute to the efficiency and durability of hydraulic systems.

The Importance of KG Hydraulic Filters

Hydraulic systems are intricate and sensitive mechanisms that rely on the precision of their components to function effectively. Any form of contamination, whether it be particles, water, or other foreign substances, can lead to catastrophic failure. This is where KG hydraulic-filters come into play. They act as guardians, diligently removing contaminants and ensuring the hydraulic fluid remains clean and debris-free.

The consequences of neglecting hydraulic filtration can be dire. Contaminants can cause wear and tear on vital components like pumps, valves, and cylinders, increasing maintenance costs and downtime. Moreover, contaminated hydraulic fluid can reduce the efficiency of a system, decreasing performance and productivity. Investing in high-quality hydraulic filters is important to maintain the health and longevity of your hydraulic system.

Types of Hydraulic Filters

These filters come in various types, each designed to address specific filtration needs within a hydraulic system:

- Suction Filters: These filters are in the inlet line of the hydraulic pump and are responsible for removing larger particles and debris from the incoming fluid. Suction filters prevent contaminants from entering the hydraulic system in the first place.

- Pressure Filters: Positioned in the high-pressure line, pressure filters are tasked with removing smaller particles that can cause damage to sensitive components. They ensure the hydraulic fluid remains clean and free from harmful contaminants under high pressure.

- Return Filters: Located in the return line of the hydraulic system, return filters capture any remaining contaminants before the hydraulic fluid returns to the reservoir. This ensures that the fluid is clean and ready for reuse.

Best Practices for Optimal Hydraulic Filter Maintenance

Maintaining hydraulic filters is crucial to ensure their effectiveness and extend their lifespan. Here are some best practices to follow:

- Regular Inspection: Perform routine inspections of the filters to look at the signs of wear, damage, or clogging. Replace filters as needed to prevent contaminants from bypassing the filter media.

- Filter Element Replacement: Replace filter elements at recommended intervals to maintain filtration efficiency. Using genuine KG filter elements is essential to ensure compatibility and performance.

- Monitor Pressure Drop: Monitor the pressure drop across the filter. A notable increase in pressure drop may indicate a clogged filter element that needs replacement.

- Cleanliness is Key: Ensure the surrounding environment is clean to reduce the likelihood of contaminants entering the hydraulic system. Regularly clean the reservoir and filter housing.

- Proper Installation: Follow manufacturer guidelines for correctly installing hydraulic filters to prevent leaks and ensure proper filtration.

- Contaminant Analysis: Periodically analyze the hydraulic fluid for contaminants and take corrective actions if necessary. This proactive approach can help to identify issues before they escalate.

- Stay Informed: Stay updated on the recent developments in hydraulic filtration technology to make informed decisions regarding filter selection and maintenance.

Conclusion

KG hydraulic filters are indispensable components in maintaining the health and efficiency of hydraulic systems. By investing in the correct type of filter and adhering to best practices for maintenance, you can safeguard your hydraulic system from costly breakdowns and downtime.

At KG India, we offer a wide range of high-quality hydraulic filters tailored to your needs. Our commitment to excellence ensures that your hydraulic systems remain in peak condition, providing reliable and efficient performance.

Whether you require suction filters, pressure filters, return filters, or any other hydraulic filtration solution, visit https://www.kgindia.co.in/ to explore our offerings and take step towards ensuring longevity and optimal performance for hydraulic systems.