The Prospect and History of Laser Marking

In the realms of business and manufacturing, laser marking technology is undergoing a remarkable evolution, bringing unprecedented innovation and efficiency to enterprises at an astounding pace. This article explores the leading position of this technology in the business landscape, with a particular focus on the future prospects of laser marking technology, unveiling their role in the industrial production domain. Let us together delve into how laser marking machine is redefining the face of manufacturing on a global scale.

Laser marking machines can create precise and durable markings on various materials, bringing unique marking convenience to various industries. This article will conduct an in-depth analysis of the laser marking machine market, discussing its current development status, competitive landscape, and trend of fiber laser marking machine

Market Status

Firstly, the market competition is intense, with major enterprises launching products with their own features and advantages to compete for market share. Secondly, there is a serious homogenization of products, as many manufacturers focus only on the performance indicators of the products, neglecting aspects such as intelligence and aesthetics. Thirdly, after-sales service lags behind, and users face many challenges in purchasing and using laser marking machines, affecting the market competitiveness of the products.

Competitive Analysis

Laser marking technology covers various types, including fiber laser marking machines, CO2 laser marking machines, and UV laser marking machines. Each type has its own characteristics and is suitable for different marking ranges and industries.

For example, CO2 laser marking machines are mainly used for marking materials such as plastic, rubber, and leather, while fiber laser marking machines are widely applied to marking metals and silicon wafers. As for UV laser marking machines, they focus on fine and special material marking and engraving.

Branding Effect

Brand differences are not significant. Although there are performance differences among various types of laser marking machines, in terms of overall performance, the competitive gap between products from different manufacturers in the market is not substantial. Users often pay more attention to factors such as product price, performance, and after-sales service.

Fiber laser engraving machines demonstrate vast application prospects in the manufacturing industry. They can not only achieve product marking and engraving but also excel in areas such as laser welding, laser drilling, and laser cutting. With the continuous increase in demand for product personalization and customization, the role of fiber laser marking machines will become more prominent, including rapid operation, flexibility, and high precision, can perfectly meet the diverse requirements of different products for personalization and efficient production.

Laser Engraving & Etching Evolutions

Advancements in Laser Technology (2000s):

The 2000s saw significant advancements in laser technology, including the development of more efficient and powerful lasers.

Fiber lasers gained popularity for their reliability, precision, and suitability for a wide range of materials.

Diverse Material Applications (2010s):

Laser marking expanded to include a broader range of materials beyond metals and plastics. Applications extended to ceramics, glass, and even organic materials.

High-precision marking and intricate designs became possible, enabling the technology to be used in areas such as medical device manufacturing and jewelry.

Integration with Automation and Industry 4.0 (2010s-2020s):

Laser marking systems became integrated into automated production lines, contributing to the principles of Industry 4.0.

Increased connectivity and data exchange allowed for more efficient and traceable marking processes.

Green and Ultrafast Lasers (2010s-2020s):

The development of green and ultrafast lasers enabled more precise and fine markings. Green lasers are suitable for materials that do not respond well to traditional infrared lasers.

Ultrafast lasers, such as femtosecond lasers, allowed for minimal heat generation during the marking process, reducing the risk of damage to sensitive materials.

Medical and Semiconductor Applications (2020s):

Laser marking found applications in the medical field for marking surgical instruments and medical devices.

Semiconductor industry applications expanded, with lasers being used for marking and wafer processing.

3D Laser Marking:

The ability to perform 3D laser marking on curved or irregular surfaces became more prevalent, opening up new possibilities in product design and customization.

Ongoing Innovations and Customization (2020s-2023):

Innovations continue to focus on improving marking speed, precision, and versatility.

Customization and personalization of products through laser marking have become increasingly popular.

Prospect and History of Laser Marking

Laser marking technology is poised for broader applications and development. Its precision and speed will be further enhanced, gradually evolving towards intelligence. The significance of laser marking technology in manufacturing, smart logistics, medical, and other fields will notably increase.

Intelligent and Integration

With the application of artificial intelligence technology, automated laser marking machines will become more intelligent. Through the coordination of sensors and control systems, it can achieve functions such as automatic adjustment of marking parameters and automatic detection of material positions, significantly enhancing the level of equipment intelligence. Laser automation will closely integrate laser marking machines with other devices to achieve unmanned production.

Future laser marking machines will possess stronger learning and adaptation capabilities, automatically adjusting parameters to accommodate various marking materials. The implementation of Industry 4.0 will drive the development of laser marking machines towards high-end, enabling better performance in digitization, networking, intelligence, and modularity.

Compact and Portable

Desktop laser marking equipment is often cumbersome to install, operationally complex, and occupies a considerable amount of space. With the advancement of laser technology, the size of automated laser marking machines is becoming smaller, making them easy to carry and install. This makes their application more convenient in some special scenarios, as they can be flexibly applied on production lines and moved to different workstations.

Portable handheld laser marking machines are gradually becoming the preferred choice across various industries. Upgraded from traditional desktop marking machines, they not only inherit the excellent features of high marking precision, wide pulse width range, high peak power, high frequency, and beam quality but also introduce new advantages such as compact size, easy learning, and energy efficiency.

Evolution of Laser Marking Applications

Electronics Manufacturing Industry:

Automated laser marking system have unique advantages in the electronics manufacturing. They can perform high-precision marking on electronic components, facilitating product identification and traceability. Applying them to electronic production lines can significantly improve production efficiency and product quality.

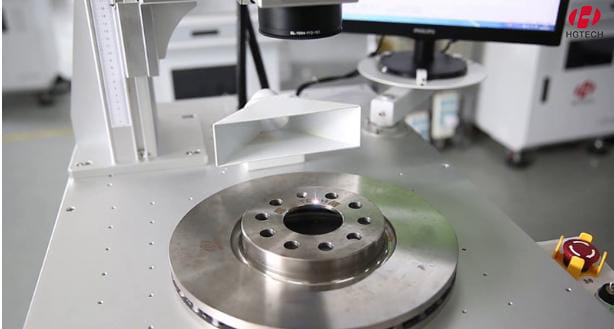

Automotive Manufacturing Industry:

In the automotive manufacturing process, marking components is a crucial step to ensure quality and traceability. Automated laser marking machines can flexibly achieve marking on various materials, not only possessing high efficiency but also adapting to the complexity of automotive component surfaces.

Packaging Industry:

In the packaging industry, product labeling is essential to ensure the accuracy of product information and traceability. Automatic laser marking machines can directly mark text, patterns, and barcodes on packaging, providing reliable identification for products.

Medical Device Industry:

Laser marking in the medical device industry, especially its application on stainless steel medical devices, demonstrates its unique advantages in the field of surgical instruments.

Laser marking machines can achieve high-quality marking on the surface of stainless steel. Its outstanding performance in corrosion resistance, passivation resistance, and resistance to high-pressure sterilization ensures the durability and stability of the markings. In addition, laser marking machines have advantages such as high precision, minimal damage, and strict three-dimensional spatial positioning, making them widely used in the manufacturing of medical devices.

For precision and safety-critical products like surgical instruments, the application of laser marking machines not only achieves high-precision marking but also contributes to improving production efficiency and product quality. Therefore, the prospects for the application of laser marking machines in the medical device industry, especially on stainless steel medical instruments.

The laser engraving & etching evolutions reflects the ongoing advancements in laser technology, increased versatility, and the integration of laser marking into various industries and manufacturing processes. As technology continues to progress, it’s likely that new applications and improvements will continue to emerge.

Visual Positioning Brings New Possibilities to Laser Marking

The integration of vision technology has brought about fresh possibilities for the laser processing industry. Continuous technological advancements have significantly elevated the precision, intelligence, and automation level of laser marking equipment through the implementation of visual positioning systems. This enhancement aligns with the modern industrial demand for large-scale production of high-quality products, reducing defect rates, achieving effective cost control, and injecting powerful momentum into the production development of enterprises.

Laser Marking

Laser marking guided by machine vision is particularly suitable for scenarios where the material is fragile, the target size is small, high positioning accuracy is required, and large-scale marking is needed. This technology significantly improves production efficiency and ensures the consistency of product quality.

Laser Cutting

The application of machine vision technology in laser cutting enables precise guidance for the cutting process, ensuring accurate cut lines, smooth edges, and effortless cutting of various desired shapes and sizes. Various laser cutting methods, including laser vaporization cutting, laser melting cutting, laser oxygen cutting, and laser scribing, can achieve more refined and efficient operations under the control of machine vision.

Laser Welding

In the welding of precision instruments, laser welding occupies a significant position due to its characteristics of no welding pollution and no deformation, with machine vision guidance enhancing its capabilities. Its applications cover areas such as automotive body steel plate welding, battery welding, pacemakers, and sealed relay batteries, providing efficient and reliable solutions for these fields.

As the modern applications of laser marking continue to expand, there is a growing demand for equipment systems to be lightweight, automated, intelligent, efficient, and highly integrated. The successful development of new high-power fiber laser technology will undoubtedly inject powerful impetus into meeting these demands.

Market Forecast

The laser checking machine market is supposed to keep on filling consistently before very long, and the market size will grow further. As per statistical surveying associations, the worldwide laser stamping machine market will develop at a CAGR of over 10% before very long, and the market size will arrive at more than $10 billion by 2025.

In conclusion, the widespread application of machine vision technology in the field of laser processing has injected new vitality into the industry. Increased production efficiency of laser marking, machine vision guidance has brought forth fresh possibilities for laser processing technology. The future of laser marking machines, the growing demand for equipment that is lightweight, automated, and intelligent underscores the significance of successful developments in new high-power fiber laser technology. This success will propel the entire industry towards greater efficiency, innovation, and integration. This evolving trend will provide more reliable and efficient solutions for manufacturing, automotive industries, medical device manufacturing, and other fields, injecting powerful momentum into the future prospects of laser processing.