The Growing Demand for DC Motors in the Electric Vehicle Market

In recent years, the global automotive industry has experienced a remarkable shift towards sustainable and eco-friendly technologies. As electric vehicles (EVs) continue to gain traction, the demand for efficient and high-performance components has surged, prominently highlighting the significance of DC motors. In this article, we delve into the intricacies of the growing demand for DC motors in the electric vehicle market, exploring the reasons behind this trend, the role of DC motor manufacturing, and the influence of factors like motor winding machine price.

The Rising Tide of Electric Vehicles

The automotive landscape has undergone a revolutionary transformation, with electric vehicles emerging as the vanguard of eco-conscious transportation. DC motors, or direct current motors, have emerged as key players in this paradigm shift due to their unique attributes that align with the requirements of EVs. Unlike their internal combustion engine counterparts, electric vehicles depend on electric motors for propulsion, making the choice of motor technology pivotal.

DC Motor Advantages in Electric Vehicles

Efficiency: DC motors boast high energy efficiency and exhibit minimal energy losses, ensuring optimal use of the available battery power. This efficiency translates to extended driving ranges and enhanced overall performance.

Simplicity: DC motors are relatively simpler in construction compared to other motor types, reducing maintenance complexities and contributing to the overall reliability of electric vehicles.

Instant Torque: DC motors offer instant and consistent torque, resulting in swift acceleration and smoother driving experiences. This characteristic is particularly beneficial in urban settings and stop-and-go traffic.

Regenerative Braking: DC motors facilitate regenerative braking, a feature that converts kinetic energy back into electrical energy during deceleration, thereby increasing the overall energy efficiency of the vehicle.

The Crucial Role of DC Motor Manufacturing

Behind the scenes, the increasing demand for electric vehicles has led to a parallel surge in the production of DC motors. DC motor manufacturing has evolved significantly to meet the unique demands of the electric vehicle industry. Manufacturers are investing in advanced technologies to enhance motor efficiency, durability, and performance.

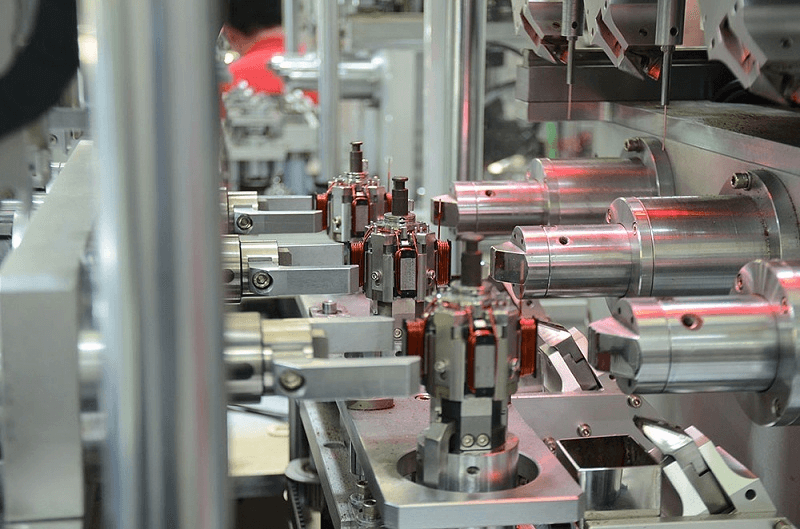

The process of creating these motors involves intricate engineering and precise assembly. Innovations in materials, design, and manufacturing techniques have paved the way for lightweight yet robust DC motors, contributing to the overall weight reduction of electric vehicles.

Influence of Motor Winding Machine Price

One of the critical components of DC motor manufacturing is the winding process. Motor winding involves the careful arrangement of coils to generate electromagnetic fields, which are essential for motor operation. The cost of motor winding machines, often measured by the motor winding machine price, plays a role in determining the affordability and accessibility of DC motors.

While advanced motor winding machines can enhance production efficiency and yield, their costs can impact the final price of the electric vehicles. Balancing quality and cost-effectiveness is crucial for manufacturers to maintain competitive pricing while delivering reliable and high-performance DC motors.

FAQs

Q1: Why are DC motors preferred for electric vehicles?

A1: DC motors offer advantages like high efficiency, instant torque, simplicity, and regenerative braking, making them an ideal choice for electric vehicle propulsion.

Q2: How has DC motor manufacturing evolved for electric vehicles?

A2: DC motor manufacturing has embraced advanced technologies, leading to lighter, more durable, and efficient motors suitable for electric vehicles.

Q3: How does motor winding machine price impact electric vehicle production?

A3: The cost of motor winding machines affects the overall affordability of electric vehicles, as it contributes to the final motor price and vehicle economics.

Q4: What is the future of DC motors in the electric vehicle market?

A4: DC motors will continue to play a vital role in the electric vehicle market, driving innovation in motor technology and sustainable transportation.

Conclusion

In conclusion, the automotive industry’s pivot towards electric vehicles has propelled the demand for DC motors to unprecedented heights. Their efficiency, simplicity, torque characteristics, and regenerative capabilities align seamlessly with the requirements of electric propulsion. DC motor manufacturing has risen to the occasion, incorporating cutting-edge technologies to produce motors that power the future of transportation. However, it’s essential to recognize that factors like motor coil winding machine price influence the economics of electric vehicle production.

As the electric vehicle market continues to evolve, the symbiotic relationship between DC motor technology and manufacturing processes will shape the future of sustainable transportation. Embracing the potential of DC motors is not just a shift towards cleaner mobility but also a step towards embracing innovation that drives us forward in a greener direction.